CONVENTIONAL FINISHING SOLUTIONS, FLAT BED- DIE CUTTING SOLUTION, LABEL FINISHING SOLUTIONS

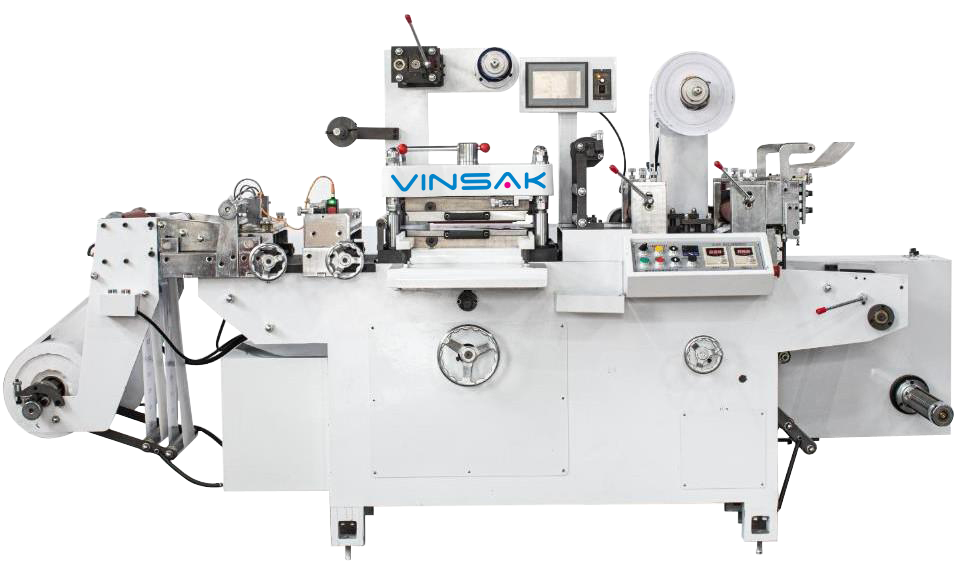

VINSAK - Flatbed Die Cutter LFD 350

The LFD350 can do hot stamping, die cutting, punching, film laminating, waste-off or slitting at one time.

The LFD350 can do hot stamping, die cutting, punching, film laminating, waste-off or slitting at one time. It is auxiliary offline equipment for the label and packaging. The flatbed die cutter carries various features including Electric Control System, Automatically Cycling Oil-Supply System to ensure stable pressure, Photoelectric Eyes guide in die cutting and hot stamping on pre-printed labels. This is a high precision equipment where web path controlled by Servo Motor.

BENEFITS

- Exceptional return on investment

- Low setup cost

- Fast implementation

- High speed and quality label production

- Prompt support countrywide

FEATURES

- Electric Control System: The main control unit adopts electric components, which ensures accurate feeding and easy operation. Two lateral registration sensors and one longitudinal registration sensor ensures high die-cutting accuracy.

- The machine uses Automatically Cycling Oil-Supply System to ensure stable pressure and service life of the machine. Photoelectric eyes guides in die cutting and hot stamping process.

- High precision, web path controlled by servo motor.

- The machine can do hot stamping, die cutting, punching, film laminating, waste-off or slitting at one time. It is auxiliary offline equipment for the label and packaging.

Technical Specifications

| Model | Max Die-cutting Size(width*length) | Max Die-cutting Speed | Unwinding/ Rewinding Dia | Overall Dimension | Machine weight | Total Power |

| LFD 320-180 LFD 320-300 LFD 320-400 | 320 x 300mm | 180 strokes/min 300 strokes/min 400 strokes/min | 500mm | 2600 x 950 x 1400mm | 1500kg approx | 7.5 kw |

| LFD 350-180 LFD 350-300 LFD 350-400 | 340 x 340mm | 180 strokes/min 300 strokes/min 400 strokes/min | 500mm | 2800 x 1100 x 1500mm | 1800kg approx | 3.85 kw |

| LFD 450-180 LFD 450-300 | 430 x 450mm | 180 strokes/min 300 strokes/min | 600mm | 2600 x 950 x 1400mm | 1500kg approx | 3 Kw |

| LFD 500-180 LFD 500-300 | 180 strokes/min 300 strokes/min | 600mm | 1500kg approx |

Video

Related Products

BOOKLET MANUFACTURING SOLUTION, CONVENTIONAL FINISHING SOLUTIONS, LABEL FINISHING SOLUTIONS ABG – Omega B5010 The Omega B5010 is a modular system…

CONVENTIONAL FINISHING SOLUTIONS, FLAT BED- DIE CUTTING SOLUTION, LABEL FINISHING SOLUTIONS Lombardi – Toro Lombardi Toro is the in-line flat…

CONVENTIONAL FINISHING SOLUTIONS, LABEL FINISHING SOLUTIONS, SLITTING/REWINDING VINSAK – Table Top Rewinder (TTR) The VINSAK TTR has been specifically developed…