CONVENTIONAL FINISHING SOLUTIONS, LABEL FINISHING SOLUTIONS, SLITTING/REWINDING

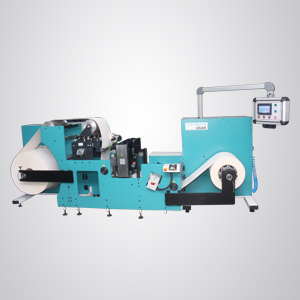

Vinsak -USAR (Universal Slitter and Rewinder)

When it comes to high‐resolution security printing with customizable finishing solutions, VINSAK USAR is the perfect solution.

When it comes to high‐resolution security printing with customizable finishing solutions, VINSAK USAR is the perfect solution. The machine is modular in nature. Slitter re‐winder, die‐cutting, 100% inspection system, inkjet systems, digital cold foiling etc. can be configured as per customer’s requirement. With all major components driven by servo motors, the equipment runs at a speed of up-to 300 meters per minute.

It is backed by powerful software and features a HMI display for easy job set‐up and single window operation.

- Twin Rewind

- Digital Cold foiling

- Variable data printing

- Venturi trim extraction

- Static elimination bars

- Semi Rotary Die cutting 10-24”

- Razor and Crush Slitting (knife box)

- Die cutting with servo re register (10”‐24”)

- 100% Inspection Camera

- High Build Digital Varnish

- Auto disengage knife box

- Missing Label Detection with vision camera

- Offline Knife setting fixture with 2 knife Shafts

- Flag and splice detection including error replacement

- Matrix stripping section, Air mandrel, Matrix break sensor

- Turret Rewinder

Variable Data Personalization

VINSAK Inkjet systems are best known for quality security printing of Bar-codes, QR codes, Variable data, 1 D images, numbering etc. It can print on a variety of substrates such as offset papers, WADS, Coated Paper, Glossy Paper, Holograms, PET, and BOPP etc. The machine can incorporate one or more of the following heads to cover the entire web width requested:

- VINSAK 1200‐K (Multiples of 108 mm Print width)

- VINSAK 720i (Multiples of 72 mm Print Width)

- VINSAK TIJ (Multiples of 12.5 mm Print Width)

- VINSAK HB (Multiples of 70mm Print width)

Smart‐ Strip Waste Removal System

Completely modular machine designed to meet the increasing demands of today’s Digital converting, security, printing and label industry. VINSAK USAR with Camera Inspection system and VINSAK Inkjet systems are best known for quality security printing of Bar-codes, QR codes, Variable data, 1 D images, numbering etc.

USAR High Performance Slitter with dual Rewind Mandrel

Completely modular machine designed to meet the increasing demands of today’s converting, security, printing and label industry.

- Pneumatic expanding un-wind and rewind mandrel, variable speed and tension control system.

- Digital Programmable feature HMI with latest new job setup data.

- This USAR machine is available in different web width 330mm, 450mm & 530mm with 300m/min maximum speed.

- Electronic web guide system, ultrasonic sensor suitable for opaque and clear substrates.

- Choice to rewind mandrel from 25mm to 76mm

USAR with Heavy Duty Inkjet System for Substrates up-to 800 microns

The 700 GSM Cardboard paper roll has dimensions of 1100mm diameter with a core of 6”, 10” and 12”. The entire Web path is re designed to suit these core diameters and handle the Board across idle rollers with a diameter of 100m or higher to ensure that there is no cracking of the board.

The wads are punched off line on a ram punch and are printed in a nested manner to save material (See image attached). The ink jet layout is specifically created for the new workflow and can accommodate this layout. This workflow ensures error free printing with complex layouts and links to the correct databases to run random numbers as well 2 D codes.

Digital Cold Foil Stamping Machine

- The VINSAK USAR Digital Cold Foil Stamping machine. Offered as a premium solution for high end label finishing with options of

- Digital cold foiling

- High Build Varnish up-tp 150 Microns

- Digital Braille

- Digital Over varnishes for Spot or Full coverage.

USAR for film and Lami-tube

The VINSAK USAR for Film and Lami-tube machine compact in size. Equipped with Special idle rollers to handle crease free film slitting as well as individual lay on rollers on the rewind, this version is ideally suited for flexible packaging printers for handling BOPP /PVC/PET films as well as Multilayer Lami-tube materials.

Optional features include integration with Slave units of 100% defect detection systems for ensuring fault removals detected upstream in the printing process.

USAR Lite

The VINSAK USAR Lite machine is compact in size. This model is specially launched for onsite applications where space is a constraint and work includes normal VDP printing using ink jet systems and a slitting and rewind system for light duty operation.

Digital Cold foiling Module:

VINSAK digital cold foiling module which can be retrofitted to new or existing USAR Machine. The digital cold foil solution is based on Ink Jet printing and conventional metallic foil to provide a higher quality finish and enable the use of security and decorative holographic images within the foil. Variable QR codes done with foil can also be created for High security applications. Same unit can also be used for applying Lamination films in partial or full width. Optional Friction shafts in the foil unwind and rewind allow foil saving in the width side.

Re Registered / Semi-rotary Die-cutting System:

The VINSAK semi-rotary and re-registered die cutting machine with die tool lift. The Rotary die cutting unit in the USAR can also be configured to a semi rotary mode. In semi rotary mode a die cut repeat of between 50mm (2″) to 622mm (24) can be achieved, when in full rotary mode the minimum repeat is the cylinder diameter of 304.8mm (12.0″). The register mark sensor detects the register marks on the web. This can be repositioned across the web using the adjustment rail. Semi Rotary allows for the use of a single magnetic cylinder for multiple repeats thus making job changeovers economical and fast for short runs.

Technical Specifications

| Inside and outside winding. |

| Efficient web tension control. |

| Speed up to 300 meters per minute. |

| Standard Scissor slitting unit including knives. |

| Choice of rewind mandrel from 1”, 1.5”, 2”, 3”, 6”, 10” & 12”. |

| Quick release/removable nip roller with pneumatic pressure control. |

| 700mm maximum unwind diameter (option to upgrade up to 1000mm). |

| Automatic stop of complete roll; at diameter: at label count or meter count. |

| Adjustable splicing table with pneumatic clamps for removal of waste product. |

| Maximum rewind up to 1000mm in single rewind mode & 450mm in dual rewind. |

| 25/38/76mm un-wind mandrel with servo driven or pneumatic brake tension control. ( Adapters for 6” or 152 mm cores as well) |

| Electronic web guidance with ultrasonic sensor suitable for opaque and clear substrates. |