CONVENTIONAL FINISHING SOLUTIONS, FLAT BED- DIE CUTTING SOLUTION, LABEL FINISHING SOLUTIONS

Petrel Security Ink

Blind inks are inks which have visually the same red colour, but one of those two inks will appear under a red filter, whilst the second one will disappear.

Petrel Security Ink

Blind inks are inks which have visually the same red colour, but one of those two inks will appear under a red filter, whilst the second one will disappear.

This is used for obtaining the apparition on a text and to establish its authenticity.

On the left side: with the red filter. On the right side, without the red filter.

Numbering inks are mainly used by letterpress for the numbering of various security documents. Consequently their viscosity is suitable for this type of printing process.

They all have a verygood light fastnes of 7 on the blue wool scale.

In addition to their visible colours, they can be:–

- fluorescent in green, yellow, or red

- migranting in red or pink

- they can be used on papers of 90gsm maximum, but not a coated paper, nor on plastic, nor on metallised supports.

This family of inks, always of black colour, is used for printing security documents.

By using specific pigments which give a conductiblilty to those inks, and therefore to the printed area, authentification of the document is made by using a special Bip-Pen which will emit immediately a green light if the document is the original, or a red light if the document is not the oiriginal. The Bip-Pen is sold by Petrel.

Those inks can be printed in offset, water-based or solvent based flexography, solvent-based silk-screen, and have only a black colour.

This new family of inks can be printed by offset, letterpress, silk-screen, flexography and gravure and is used in high security documents. Once printed inks are totally invisible, and will react to a Infra-Red laser by a visible colour emission.

The reaction will be the following: under the excitation wavenlengh of 980nm (infra-red), the emission will occur either in blue at 470nm, or in green at 545nm or in red at 660nm.

The strongest emission will be in green, whilst the red and blue emissions are weaker.

Petrel can deliver Infra-red Lasers with this excitation wavenlengh at 980nm.

Coin revealble inks are often used in security for obtaining the apparition of a hidden message on the original document, and sometimes in Direct marketing.

After printing and drying, this ink is totally invisible, but it is revealed by using a simple coin, (preferably made of copper or brass) rubbed on the printed area. Then the print will appear irreversibly in grey.

Coin revealable inks exist for offset, letterpress and flexography.

Seri-Paint inks are printed only by silk-screen and are used for printing a painter’s palette. A children’ book will contain this palette with a paint-brush. As a game, a child will use this palette with his wet paint-brush exactly as a standard painter’s palette for painting. This painter’s palette can be used only one time.

Range of inks, visible in black, used for printing various shades of grey colour, which, when being wet with a small quantity of water or simply with a wet finger, will become coloured (several colours are available).

A printed document will easily switch from black to a colour just by wetting this document. Such a document will be authentificated and distinguished from a counterfeited which will not show this reaction.

Those inks are only printable by letterpress or dry offset. The coloured reaction is made once and is irreversible.

In opposition to thermochromic inks, the thermic inks are whitish after printing and become coloured irreversibly when they are subject to high temperatures. 2 Temperatures are available:

A first family will react at a temperature of 75°C, and above this temperaure, the red or black coloration will remain visible.

A second family will react to 95°C with a coloration in blue, or black, or red, or green, and this coloration is irreversible only if a temperature largely superior to 95° is reach.

They can be used in offset, flexography, gravure and silk-screen. Inks are invisible when printed, but are revealed by a special reactive supplied with our ink. Reaction of coloration is irreversible. This allows a very easy and quick authentication.

Watermark inks can be printed in offset, letterpress and flexography; they are used for printing a watermark which will give a certain transparency on a paper, not exceeding 90gsm. As those inks are rather oily, it is advisable to print them on the back side of the paper and to avoid overprinting them.

The effect of transparency will be reach after a period of 24-48 hours, because ink needs that time for a complete migration through the paper. Consequently a coated paper cannot be used.

This family of inks showing a change of colours according to the angle of view is widely used in fiduciary fields and is used on many banknotes in the world, in order to avoid colour photocopies.

Our RVI inks (Reflexion Variable inks) use very special pigments, and printing process used with those inks are silk-screen, flexography and gravure. Offset cannot be used.

The best effect will be obtained with a rather thick deposit of ink on the support, and with some references of RVI inks it is advisable to underprint a black ink. Hot-air drying and UV drying formulations can be used, but hot air drying will give best results regarding the change of colours according tio the angle of view. For example, at 90° the colour of the print will be visible red, then when varying the angle of view, the colour will pass to gold, then yellow, and green.

Due to this phenomenon, it is very easy, without any specific material, to distinguish an original from a photocopy. Some references are specifically reserved for high security documents, such as passports, Identity documents, visas, banknotes, but other references can be used on less sensible documents.

As an alternative to iridescent inks which cannot be used in offset, the pearlescent inks can be printed by offset and letterpress.

Those inks, printed preferably on a coated paper, will produce a pearlescent effect which cannot be reproduced by a scanner or a photocopy

For a print on standard offset paper, we recommend to deposit first a varnish which will avoid that the pearlescent ink will be absorded by the paper. The deposit of pearlescent ink must be important.

Pearlescent inks can be slighly coloured but in that case the colour will be very pastel.

Iridescent inks are widely used on most high security documents, such as passports, banknotes and visas.

They are manufactured with very special pigments providing a change of colours with a very efficient flip-flop effect; they are almost transparent under a 90° view angle and coloured under a 45° angle.

They are very usefull against colour photocopies because their appearance change totally between the original and a photocopy.

Various colours are available for flexography, silk-screen and gravure, but offset or letterpress cannot be used with those inks. With flexography the deposit must be important with a minimum of 15 to 20cm3/sqm.

Iridescent inks can have also 2 colours, for example red and blue, or green and blue, or green and gold.

Photochromic inks are invisible inks which, gradually under exposure to Ultra-Violet rays, become coloured, in blue, or violet. This reaction of coloration is reversible, once the document is no more exposed to UV rays.

UV rays are emitted by the sun, a U.V. lamp or a photographic flash.

Instead of being invisible, those inks can be also coloured and some variations are possible:a yellow ink will switch to green, a red ink will switch to violet./p>

Printing process can be dry offset, flexography, silk-screen and gravure, but in any case the deposit must be important. Wet offset canoot be used.

Thermochromic inks can loose their original colour when the temperature increase and this is reversible.

For example a visible blue 27°C thermochromic ink will be coloured up to 27°C and will become progressively transparent when the temperature will increase above 27°C.

When the temperature will come back below 27°C , then the ink will be again visible blue. This reaction is always reversible.

Family of inks, usually of pastel colours, manufactured with no black or grey colour, and which become invisible under some specific readers.

For those inks, we distinguish 3 uses:

- For optical reading: ink is used for printing small coloured squares, used as a frame, inside of which a black or blue hand-writting will me made. Then the reader which has a specific filter, will detect and read only the inside of the frame, but not the frame itself because of its filter.n Optical readers are available from for example IBM, SCAN DATA, HONEYWELL BULL, FARRINGTON, CONYTROL DATA.

- For check scanning: mainly used in the scan of Euro checks. The background of checks is printed with inactinic inks, which can be erasable or fugitive or standard. Bank scanners are numeric and they are adjusted for keeping in memory only the variable datas from the check. For the background of checks, it is essential that the contrast value of this background is superior to 60%.

- Black infra-red: those black inks are formulated in order to be transparent under infra-red of above 700nm. They are used for hidding for example a barcode, by their black colour, but this barcode is still readable under Infra-red.

Phosphorescent inks are not only fluorescent under UV lights, but after extinction of the UV lights, they still continue to emit lights for a certain time, this is called after-glow.

They are mainly used in the postal sorting-out, because they are read by a phophoroscope and in that case can be printed on any paper, with or without optical brighteners. Inks are whitish and, when printed on white paper, are invisible.

Phosphorescent inks exist for flexography and silk-screen, but offset printing process is only available for printing postal stamps.

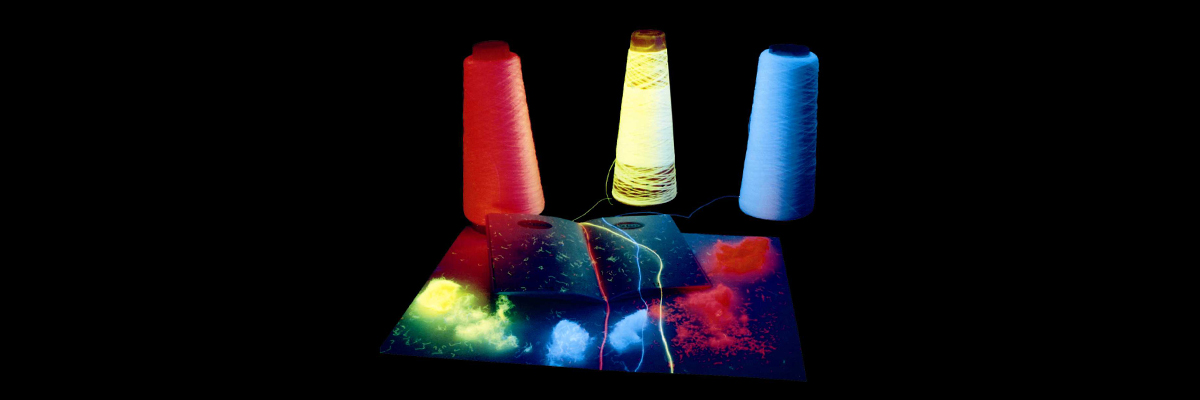

INVISIBLE AND FLUORESCENT INKS

Our company is specialised in the production of invisible and fluorescent inks.

Those inks are commonly used on all kind of security documents. Fluorescence, invisible in daylight or artificial light, becomes visible when exposed to an Ultra-Violet light (Black light or Wood light) and does not produce, as it is the case with phosphorescence, any after-glow (persistence of fluorescence after switching off the Ultra Violet light).

The choice of fluorescence shade is virtually limitless, but black and white fluorescences do not exist. Those inks can be printed in all printing processes and have to be used on papers without brightening agent (UV dull papers).

Against falsification made by scratching or erasing, it is necessary to use erasable and reactive inks.

ERASABLE INKS

Those inks can be printed by wet offfset with conventionnel drying.

The adhesion of those inks on the paper is designed for being sufficiently weak in order that when a falsificator tries to scratch off or to erase the printed documents, the erasable ink will disappear before the hand-wrting, and this will reveal the falsification.

REACTIVE INKS

Also called sensible inks to solvents, those inks react to solvents, alcohol, sulfuric esthers, gasoline, pen-erasers, by either a change of colour or a discoloration.

Those inks can show two different reactions:

Either the use of a solvent will discolore the ink and the original colour will be modified, or we can hide an other pigment in this ink, (especially in the dark shades) with for example a dark blue ink which will react in red if the document is in contact with solvents.

In order to increase the security level of those inks, we can add fluorescence under 365nm and 254nm.

Almost all Pantone shades are available. Recently we have developped reactive inks which can be printed by wet offset with UV drying.Those inks are also water-fugitive but they also offer a two-fold security feature:

they become fluorescent under UV light when they have been watered.

This type of inks is used in view of an immediate revealing of the forgeries: if the printed document has been tampered with water, then, first the ink intensity will fade, and secondly when exposed under UV light, the fluorescence will be clearly visible.

When printed in dry offset or letterpress, the visible colour does not show any fluorescence but after the document has been tampered with water, the ink becomes fluorescent (mainly in blue) and the strongest effect will, of course, be achieved on non-bleached substrates.

Those inks have the particularity to react to water, hypochlorite, bases at 5%, acids at 5%, ink killer pens, Ethanol Benzene 50/50, Oxydoreductor, Sodium sulphite, Glycol Ethers and Alcohol. The effect is a discoloration or a colour alteration.

They are mainly used for the printing of the background of bank checks, shares and so on. In this case when forgers try to modify document by washing them, the printed part will bleed and the forgery will be immediately discovered. Fluorescent properties can be added to those inks.

Due to their specifications, those inks can only be printed in dry offset, letterpress and flexography.

The colour density of those inks is not very high because the dyes used for manufacturing them allow only pastel shades.

Related Products

CONSUMABLES, SELF-ADHESIVE BLANKETS Self-Adhesive Blanket Self-adhesive blanket with a ground surface for 2 piece can printing and other applications requiring…

CONSUMABLES Perforation Blades Micro-Perf is ideal for perforating continuous-feed forms, creating a perforation line that remains clean with no stray…

CONSUMABLES Numbering Inks Numbering Inks Numbering inks are specially designed for numbering and magnetic applications. Get In Touch Enquiry Form…