CONVENTIONAL FINISHING SOLUTIONS, LABEL FINISHING SOLUTIONS, ROTARY/SEMI-ROTARY DIE-CUTTING SOLUTIONS

ABG - Vectra ECTR

Vectra Rewinders are one of the best in the world. Developed over many years by working closely with our customers to meet individual requirements

ABG – Vectra ECTR

Vectra Rewinders are one of the best in the world. Developed over many years by working closely with our customers to meet individual requirements, their design, engineering and capability have been tried, tested and proven. Able to work in-line, or off-line as a stand-alone solution with a separate unwind module, Vectra turret rewinders enable you to finish your customers’ jobs quickly, offer shorter lead times, reduce your inventory to improve cash flow and cut waste. Servo driven and with accurate tension control, they are smooth, reliable and capable of handling a wide range of substrates including delicate, perforated or punched products.

The Vectra ECTR is ABG’s entry level, 4 spindle turret rewinder, which is perfect for rewinding standard self-adhesive labels. It is also fully upgradable with a wide range of options, including automatic core loading, finished roll closure with print and applies label application, and their own fleyeVision 100% camera inspection system.

FEATURES

- Compact unwind – for off-line operation, a space-saving 1000mm diameter, braked unwind unit is available, with an integral roll lift, electronic web guide, adjustable splice table with clamps and auto-lift scissor slitting unit, complete with five sets of rotary knives.

- Automatic core loading – enables cores to be positioned automatically and accurately onto the rewind shaft, supplied with a storage tower or automatic bowl feeder for small cores.

- Omega/Vectra interface – allows the operator to run an Omega converting line and a turret rewinder simultaneously, with the use of a single handset.

- Nordson hot melt gluing – a programmable system which allows the operator to set up the core gluing in seconds.

Technical Specifications

| Maximum roll diameter: | 350mm |

| Web width: | 330mm or 430mm or 530mm |

| Air mandrels: | 4 off at 76mm (standard) |

| Maximum web speed: | 100mtr/min with 25-38mm dia mandrels |

| 150mtr/min with 40-76mm dia mandrels | |

| Constant torque tension control | |

| Counter: | Labels and metres |

| Web dividers: | 6 (5 lanes) |

| Touch screen H.M.I: | 8” (203mm) 10” (250mm) |

| Auto roll eject mechanism | |

| Adjustable core stop | |

Video

Related Products

BOOKLET MANUFACTURING SOLUTION, CONVENTIONAL FINISHING SOLUTIONS, LABEL FINISHING SOLUTIONS ABG – Omega B5010 The Omega B5010 is a modular system…

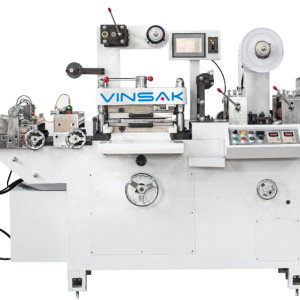

CONVENTIONAL FINISHING SOLUTIONS, FLAT BED- DIE CUTTING SOLUTION, LABEL FINISHING SOLUTIONS VINSAK – Flatbed Die Cutter LFD 350 The LFD350…

CONVENTIONAL FINISHING SOLUTIONS, FLAT BED- DIE CUTTING SOLUTION, LABEL FINISHING SOLUTIONS Lombardi – Toro Lombardi Toro is the in-line flat…